The main goal of Delta experiment is realization of a decision support system for energy efficiency and zero-defect manufacturing of production line capable of supporting the production manager with information concerning the energetic state of physical resources of the production line. The system is able to introduce appropriate measures for the energy efficiency of the line. The Delta experiment aims to improve the energy efficiency in buildings and factories, and to monitor the manufacturing process through the IoT gateway. Further, the product quality assessment is done utilizing a distributed control network and implementing complex sensor fusion, quality prediction and defect detection algorithms.

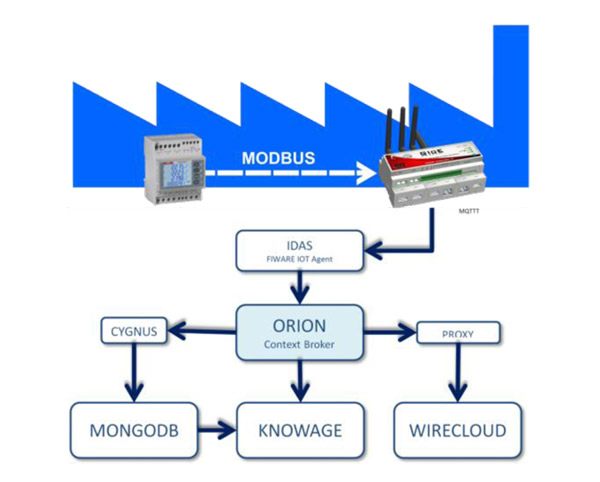

The DELTA system is composed of various sensors which provide different measurements (e.g., energy consumption, power consumption and power production), both from the machineries and in the plant. These sensors share the collected data with GIoE (Gateway for Internet of Everything by TERA). Finally, the data are transferred via MQTT to the MIDIH platform for advanced data processing and visualization. The realized system can support the production manager in the following activity:

Cloud-based solution obtained by the integration of reliable frameworks and tools (such as MIDIH components) were of great assistance during the development of the experiment system application for energy efficiency of the production line.

The important experience and the know-how deriving from the R&D activities on the quality prediction and energy efficiency experiment performed for the DELTA project have been exploited by the company for other projects. The areas studied during the project cover Industry 4.0 topics applied to the production processes for:

Nicola Prunella

nicola.prunella@terasrl.it

Leonardo Cici

leonardo.cici@terasrl.it

Tera Srl Via C. Balbo 19/D

70014 Conversano BA,

Italia