The main objective for this experiment was the improvement of the efficiency and innovativeness of FCA Supply Chain, implementing and using MIDIH solution that, by mean of both FIWARE and custom components, allows a better knowledge and understanding of events that can happen during the shipment of components from the supplier plant to the production plant.

The adoption of this solution has allowed to have information in case any issues occur, in order to improve availability and timely scheduling of the production, thanks to the real-time tracking and monitoring of materials during the supply.

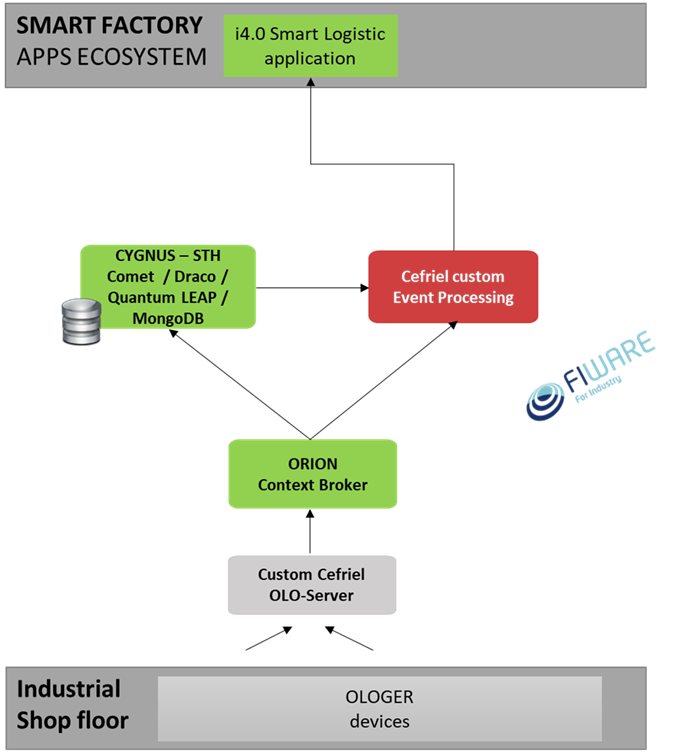

The i4.0 Smart Logistic application, developed by Cefriel, and that leverages on MIDIH Platform, has been used for the scope of this part of the CRF Lighthouse experiment. The application leverages on custom tracker devices, called Ologer (Outdoor Logistics Tracker). These devices permit the tracking of the parameters needed for the monitoring of the environmental and mechanical events impacting the components status during transportation from a starting plant to destination plant.