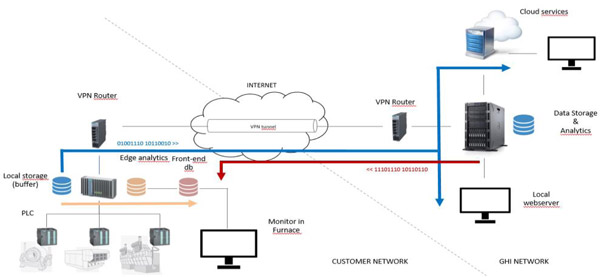

In the ENERSAL context, GHI is working on the design and development of an intelligent and autonomous energy management monitoring system that will favour the optimization of the operation of the tilting rotatory furnaces integrated on the aluminium melting process. For this, GHI has defined an architecture, both at hardware and software level, for the development of this solution.

The following components have been performed:

The development of this experiment with these new components has led to a series of improvements, some more relevant than others:

Eduardo García

egarcia@ghihornos.com

GHI HORNOS INDUSTRIALES SL

Barrio de Aperribai, 4,

48960 Galdakao

Spain