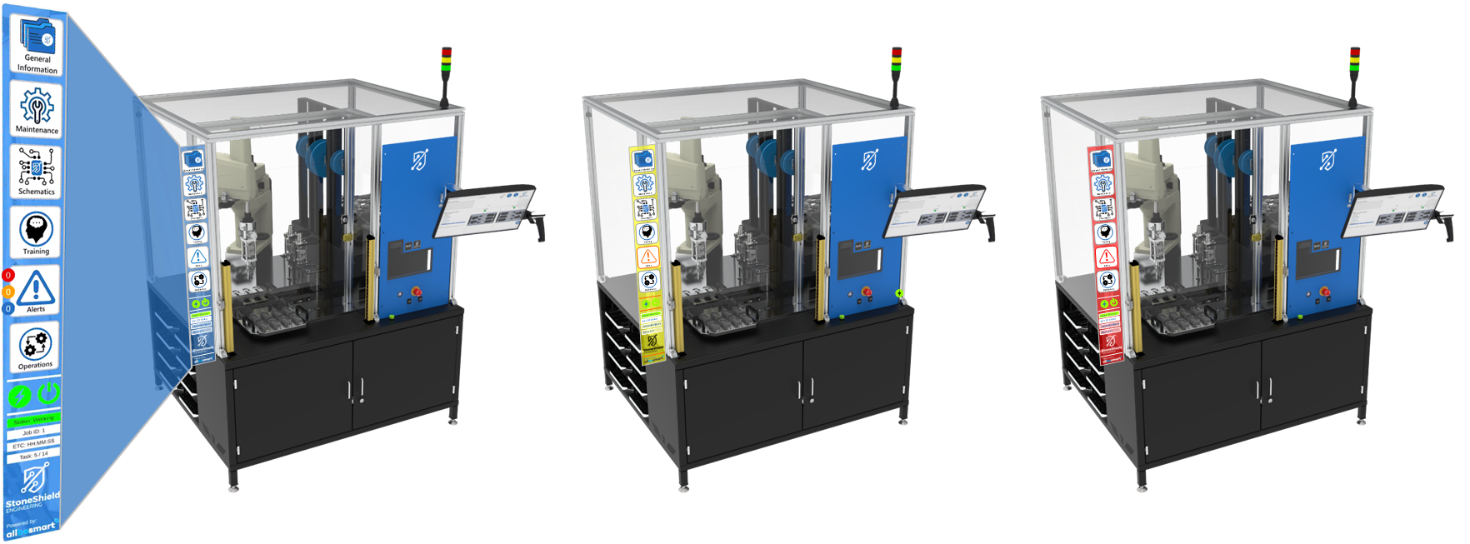

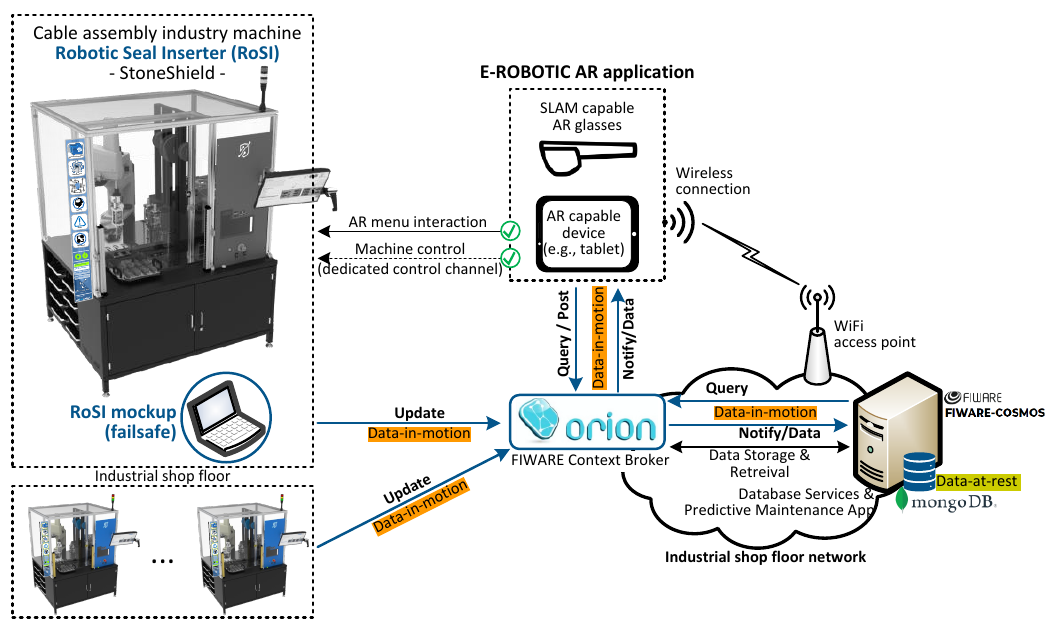

Assembly of automotive wiring harnesses is still a process with mostly manual work. Due to increasingly stringent quality requirements coupled with the demand to lower production costs and miniaturization, there is a strong move towards automation and use of robots. The main objective of the E-ROBOTIC experiment was to explore and promote the usage of AR technology on specific robotic machines targeting this industry. This goal was achieved by bringing an AR-based User Interface for a Robotic Seal Inserter, allowing an operator/technician to access and visualize machine data/information required for maintenance operations, training-on-the-job, real-time monitoring of machine KPIs. The AR interface includes a predictive maintenance scenario to explore further automation possibilities.

The FIWARE ORION Context Broker, with Mongo DB, has been used and proofed suitable for typical shop floor data exchanges. When requiring access to large files (e.g., machine manuals with hundreds of high-quality images) or streaming services (e.g., training video tutorials), a mixed approach is needed for accessing the Data-at-Rest (DaR). For such scenarios, and taking into consideration scalability reasons, the volume of data that traverses the context broker must be minimized - specific DaR resources (e.g., documents, images, videos), should be configured in the MongoDB with minimal information, sufficient for retrieving the resource from other location(s).

The targeted manufacturing companies will benefit from the following:

The overall impact for Allbesmart business is:

Paulo Marques

+351 933 221 493

Allbesmart, Lda

Avenida do Empresario

Centro de Empresas Inovadoras 1,

6000-767 Castelo Branco

Portugal