Process Genius (PG) is one of the newcomers changing the way industrial companies are managed by offering a revolutionary approach to visualize production data and bring it to the end user’s disposal.. Businesses empowered by PGplant gain the competitive edge via a significant increase in productivity. Process Genius unique multi-layered 3D user interface product, called PGplant, integrates the data from various sources and thus replaces multiple UIs of current IT systems.

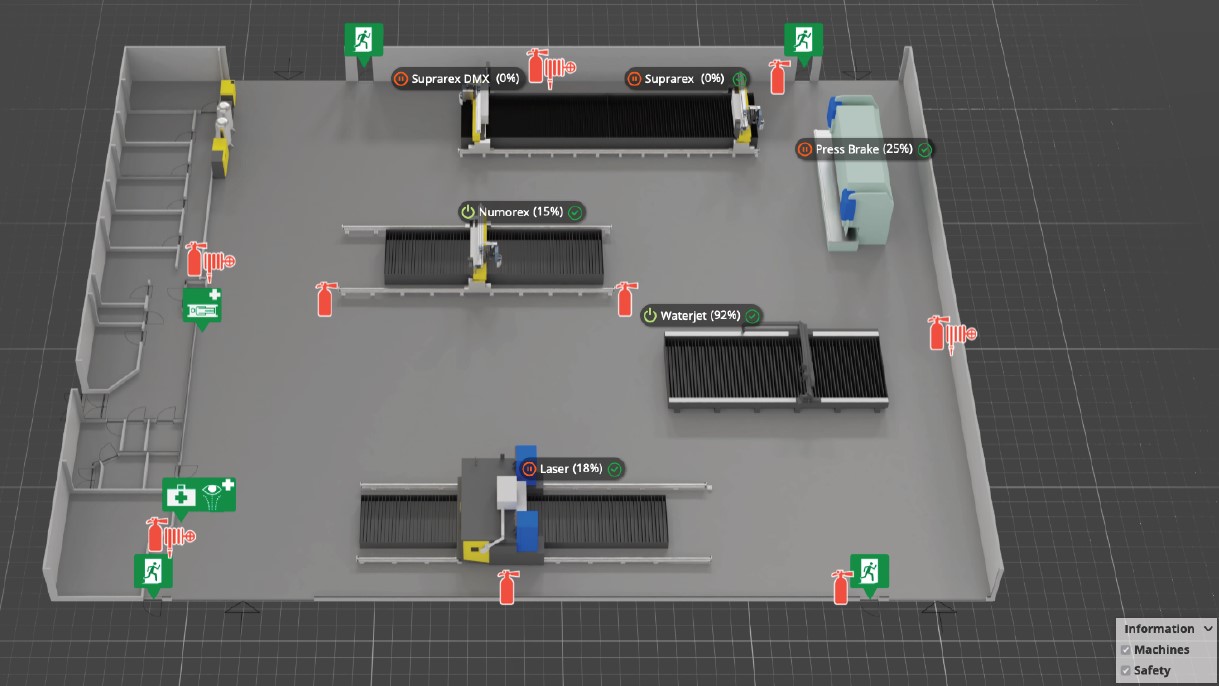

Figure 1. GUI basic process view, PGplant.

The PGplant solution provides the Industrial Internet with an attractive facade, which is based on the advanced Digital Twin concept. To improve the compatibility of the PGplant solution with standard IoT platforms and frameworks, this experiment has focused on building connectivity with MIDIH reference framework to extend the architectural capabilities of PGplant. At the same time, a strong effort has been put into optimizing the technical scalability, automating the deployment process, and completing market launch readiness to enable scalable growth on global markets.

The outcome of this combined effort has resulted in a cloud platform based product offered as an easy-to-deploy solution, which integrates with any standard frameworks via open APIs . Through the implementation of MIDIH pilots PG Plant solution has been validated in the Smart factory environment outside the domestic market and has raised larger awareness about PGplant.

By building connectivity with MIDIH reference framework, the architectural capabilities of PGplant has been expanded. Deployed automation solutions has reduced the time developers spend in server maintenance tasks. The time required to setup a new customer platform into cloud have been reduced from a 1 day job to less than 2 hours job. Data Stream(DS) service architecture and DS service API documentation created provides guidance and understanding of functionality and the integration of data from sites into the PGplant digital twin visualisation tool/platform. Technical results from the MIDIH project has enabled the platform to be used by wider audience as the platform is no longer as tied to specific hardware or measurement tools than it previously was.

The results in Midih has enabled the transfer of business model from the Service base product to more Software base product, as this enables to expand to the global markets via sub-contractors and co-operators rather than only by using in-house resources.

The first Prokosch pilot in Stuttgart has already led to sales negotiation in Germany to produce the new PGplant platform to other companies. The Second pilot platform made for Jacquet in Finland has increased the interest of their mother company, so the platform is already spreading to other facilities around Europe.