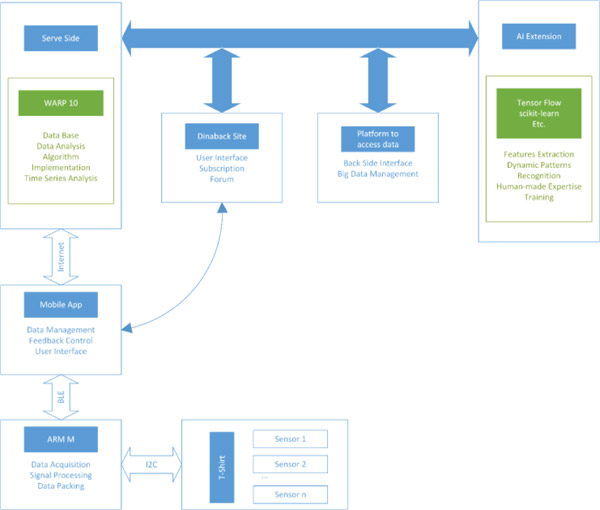

The Dynaback solution in the MIDIH experiment consists in two main parts:

The Dynaback garment underwent some considerable changes since the beginning of the MIDIH project. The size of sensors was reduced, the manufacturing process of electronics was brought closer to industrial production, the garment was designed more comfortable, accurate and compatible with the work environment.

The Dynaback garment is one facet of the project. It allows to collect data. However, the whole other objective of the project is to collect this data seamlessly, to store is and to process it.

The architecture has changed since the beginning of the MIDIH project. While originally the Mobile app was mean to communicate directly with the WARP 10 platform, we chose to include another server between the two.

The Warp10 platform was chosen because it maps well to MIDIH architecture. Many of MIDIH components are found in Warp 10. These are a few common parts of both systems:

The growing regulations might explain the need for companies to protect their workforce better. For instance, in France in the coming couple years, new legislations will force companies to assess the painfulness of the work of their employees. Dynaback could be a good candidate to fill in the gap of missing technology. It is not only growing regulations that are pushing the companies towards increased safety. The realization that injuries have an unneglectable cost for the company is encouraging them to make sure their employees are safe. Work-Related Muskulo Skeletal Disease account for Europe spending 500 billion euros a year.

Sabri Sabr Mahdaoui

sabri@dynaback-tshirt.com

Madesign LTD

11ti Avgust Str.5

1000 Sofia, Bulgaria